The aim of Task 2 was to study the multiple barrier system in the near-field of a repository, by modeling a comprehensive in-situ THM experiment at the abandoned Kamaishi Mine, Japan, where PNC (later renamed as JNC) ran an underground laboratory, with especial focus on the bentonite behavior, constitutive models and parameters. Regarding the complexity of the in-situ experiment and the corresponding schedule of experiments and numerical modeling through blind prediction-model calibration cycles in line with the progress of the experiments and the measured data availability, Task 2 was divided into three sub-tasks:

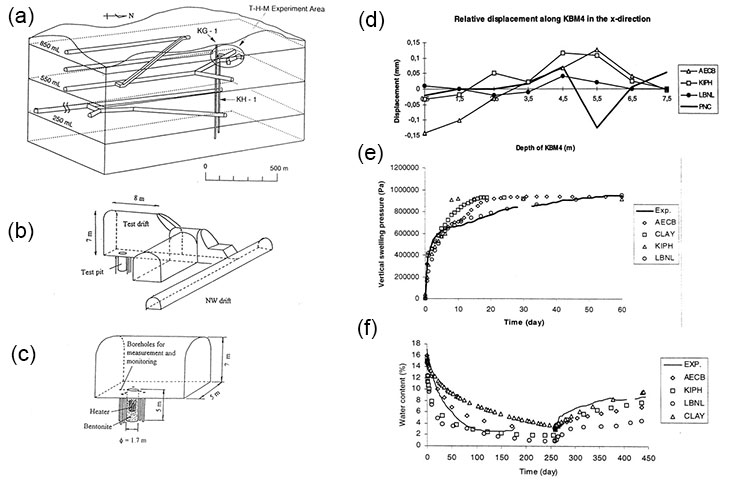

Four research teams participated in Task 2: AECB team using the FEM code COSMOS (for Task 2A and 2B, and the FEM code FRACON for Task 2C, in 3D; CLAY team using the DFN code FRACMAN and FEM code ABAQUS, in 3D; KIPH using the FEM code THAMES, in 3D; and LBNL team using the FEM code ROCMAS in both 2D and 3D. Figure 2 shows the location and layout of the in-situ THM experiments at Kamaishi Mine (Fig.2a-c), and comparisons of the modeled and measured results of the relative displacements in rock (Fig,2d), swelling pressure (Fig.2e) and water content (Fig.2e, 2f) of the bentonite as examples.

Task 2 was a great success for testing and modeling the near-field multi-barrier system behavior of GDRW repositories by, not only reliable modeling and measurements through continuous cycles of blind-prediction-followed-by-model-calibration practice in the DECOVALEX project, but also as an integrated modeling and experiment design and implementation with DECOVALEX researchers playing actual roles for in-situ THM experiments, together with the PNC scientists. The specially designed and executed laboratory tests on the bentonite during Task 2C-1proved to be important for improving material characterization as identified during Task 2B, demonstrating a good example of integrated testing and modeling approaches, as shown by reasonably good modeling results from the prediction-calibration cycles.

The main outstanding issues are the less accurate results (both measurements and modeling) for the mechanical behavior of the host rock near the test pit, due mainly to the largely unknown fracture system inside the rock around the test pit locally and at the site globally, unclear initial and boundary hydraulic conditions of the site model surrounding the test area, and EDZ effects on the surrounding rocks by the test pit excavation.